7 Reasons Why High Torque Motors Are Revolutionizing Industrial Applications

The rise of high torque motors is significantly transforming the landscape of industrial applications, driven by their unparalleled efficiency and performance capabilities. According to a report by MarketsandMarkets, the global motor market is projected to reach $40.0 billion by 2025, with high torque motors playing a crucial role in this growth due to their ability to provide exceptional power output at lower speeds. Industries such as manufacturing, automotive, and robotics are increasingly relying on these motors to enhance productivity and reduce energy consumption. In fact, high torque motors are known to improve operational efficiency by up to 25%, according to a study by the International Energy Agency. This revolution not only promises cost savings for businesses but also supports sustainability efforts by minimizing waste and enhancing reliability. As such, understanding the transformative potential of high torque motors is essential for any industry professional looking to stay ahead in a rapidly evolving marketplace.

Transforming Efficiency: The Role of High Torque Motors in Industrial Operations

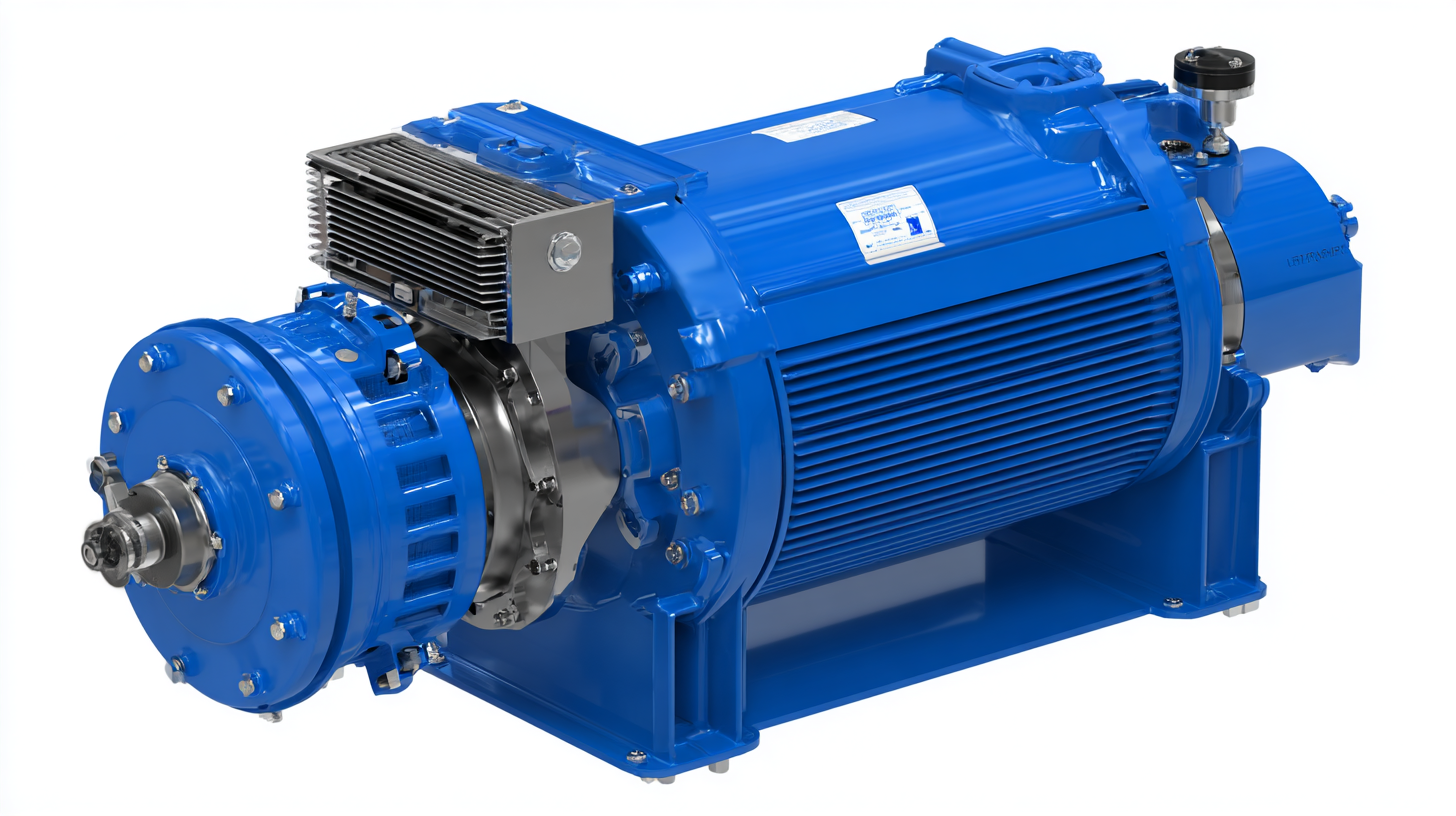

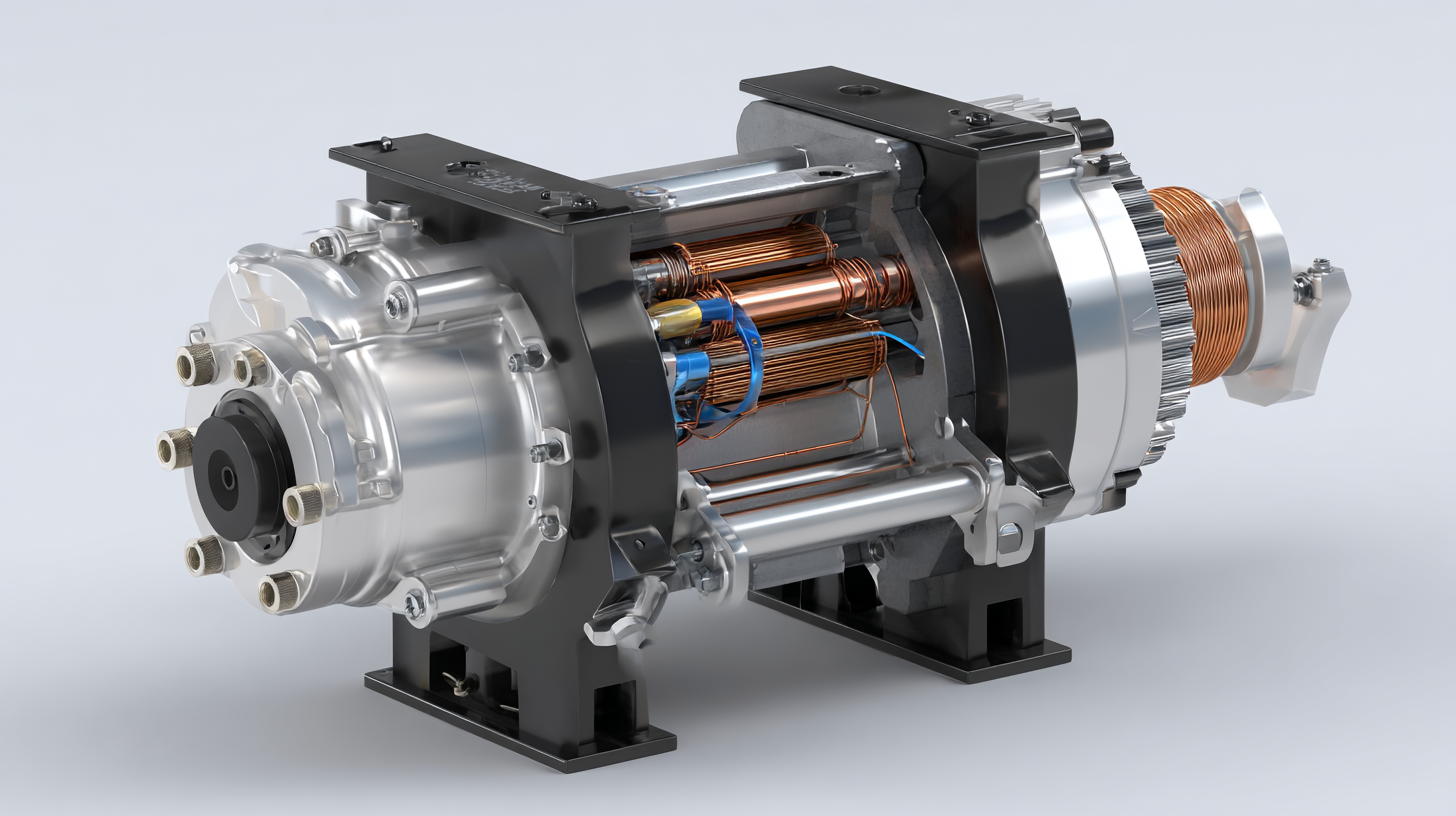

High torque motors are increasingly playing a pivotal role in enhancing efficiency across various industrial operations. These motors are specifically designed to deliver substantial torque at low speeds, making them ideal for heavy-duty applications such as conveyor systems, industrial pumps, and manufacturing machinery. By providing the necessary power to overcome resistance at startup and during operation, high torque motors reduce wear and tear on equipment, prolonging their lifespan and minimizing costly downtime.

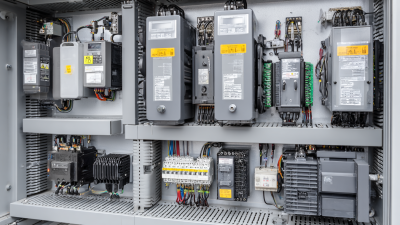

Moreover, the integration of high torque motors with advanced control systems enables industries to achieve precision in their processes. This capability not only optimizes performance but also allows for greater adaptability to varying load conditions. As these motors facilitate smoother operation and energy savings, they contribute to a more sustainable industrial landscape. The shift towards high torque motors signifies a broader trend of innovation aimed at achieving higher productivity while addressing the need for energy efficiency in an increasingly competitive market.

Unmatched Power: How High Torque Motors Enhance Performance Across Industries

High torque motors are becoming increasingly vital in various industrial applications, thanks to their ability to deliver unmatched power and efficiency. These specialized motors generate greater force at lower speeds, making them ideal for tasks that require precision and strength. Industries such as manufacturing, construction, and robotics benefit significantly from this high torque capability, allowing for smoother operations and enhanced performance. The ability of high torque motors to handle demanding loads without compromising speed or reliability plays a crucial role in increasing productivity and minimizing downtime.

Moreover, the integration of high torque motors into production lines and machinery is transforming operational capabilities. Their robustness and adaptability enable them to operate in extreme conditions where traditional motors might fail. This enhancement not only improves the overall efficiency of industrial processes but also reduces energy consumption, leading to cost savings. As industries continue to embrace automation and advanced technologies, high torque motors are paving the way for innovative solutions that cater to complex challenges, setting a new standard in performance across various sectors.

Cost Savings: The Economic Impact of Implementing High Torque Motors

The integration of high torque motors in industrial applications is yielding significant cost savings, making them a competitive choice for many businesses. The global energy efficient motor market, valued at $48.25 billion in 2023, is expected to grow to $51.65 billion in 2024 and further surge to $84.72 billion by 2030. This growth is driven by the increasing demand for energy efficiency and performance optimization in industrial processes. High torque motors enable systems to operate more efficiently, reducing energy consumption and minimizing operational costs over time.

The integration of high torque motors in industrial applications is yielding significant cost savings, making them a competitive choice for many businesses. The global energy efficient motor market, valued at $48.25 billion in 2023, is expected to grow to $51.65 billion in 2024 and further surge to $84.72 billion by 2030. This growth is driven by the increasing demand for energy efficiency and performance optimization in industrial processes. High torque motors enable systems to operate more efficiently, reducing energy consumption and minimizing operational costs over time.

Tips for businesses considering the transition to high torque motors include assessing the specific needs of their applications and calculating the potential return on investment. By investing in these advanced motors, companies can enhance productivity and reduce wear on equipment, leading to lower maintenance costs. Additionally, as industries become more aware of sustainability practices, adopting high torque motors can improve a company's environmental footprint, aligning with global energy conservation efforts.

Furthermore, incorporating high torque motors can lead to enhanced system reliability and performance, translating to reduced downtime and increased production capabilities. As these motors become more prevalent, businesses leveraging their advantages will likely find themselves at the forefront of operational excellence in their respective sectors.

Versatility in Applications: High Torque Motors for Diverse Industrial Needs

High torque motors are increasingly becoming a cornerstone in various industrial applications due to their versatility. These motors excel in tasks requiring significant force, such as heavy lifting and precision control. According to a report by the International Electrotechnical Commission, industries employing high torque motors have seen a productivity increase of up to 25% in applications such as conveyor systems and robotics. The ability of these motors to maintain consistent performance under load is a game changer for sectors ranging from manufacturing to mining.

Moreover, high torque motors are adaptable, catering to a wide array of applications beyond traditional use cases. For instance, the automotive industry utilizes high torque motors in electric vehicles, where acceleration and efficiency are paramount. A study by the American Society of Mechanical Engineers highlighted that integrating high torque motors in electric drivetrains can improve energy efficiency by 15-20%, addressing growing sustainability goals. This versatility is driving investments in high torque motor technology, making it an essential component for future innovations in industrial processes.

Sustainability and Innovation: The Future of High Torque Motors in Industrial Solutions

The integration of high torque motors into industrial applications marks a significant shift towards sustainability and innovation. As industries increasingly prioritize energy efficiency and carbon reduction, these motors play a crucial role in driving sustainable practices. The latest advancements in motor technology ensure that they consume less energy while maintaining high performance, leading to lower operational costs and diminished environmental impact. Enhanced efficiency not only aligns with global sustainability goals but also supports the growing demand for automation in industrial processes.

Moreover, the infusion of artificial intelligence in the design and operation of high torque motors is reshaping the market landscape. AI-driven innovations enable better control systems and performance optimization, further enhancing the effectiveness of these motors in various sectors. As industries gear up for a future dominated by smart manufacturing and sustainable solutions, high torque motors will stand at the forefront of this evolution, proving to be indispensable in achieving not only operational excellence but also environmental sustainability.

7 Reasons Why High Torque Motors Are Revolutionizing Industrial Applications

Related Posts

-

Addressing Common Calamities in High Torque Motor Procurement: A Global Perspective

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

How to Choose the Right Industrial Servo Motor for Your Application

-

5 Best Ways to Optimize Motor Power for Industrial Efficiency

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Future Innovations in Servo Motor Drivers Shaping Global Industry Trends in 2025