7 Essential Tips for Maximizing Performance with AC Servo Motors

In the rapidly evolving landscape of automation and industrial machinery, the importance of ac servo motors cannot be overstated. According to a recent report by Grand View Research, the global servo motor market is projected to reach USD 12.89 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.9%. This surge is driven by the increasing demand for precision control and energy efficiency in sectors such as robotics, manufacturing, and automation. However, to fully leverage the capabilities of ac servo motors, it is essential to adopt best practices that enhance their performance. Understanding the intricacies of their operation and implementing effective strategies can significantly improve efficiency, reduce operational costs, and prolong equipment lifespan. In this blog, we will explore seven essential tips for maximizing performance with ac servo motors, enabling businesses to stay competitive in a technology-driven market.

Understanding Common AC Servo Motor Issues and Their Impact on Performance

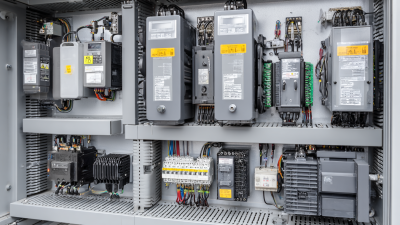

AC servo motors are renowned for their precision and efficiency, but they can face various issues that hinder their performance. Understanding these common challenges is essential for maintaining optimal motor operation and reducing downtime. Factors such as inadequate power supply, improper motor tuning, and environmental conditions can significantly affect an AC servo motor’s functionality.

To address these concerns, one effective tip is to ensure that your power supply is stable and meets the motor’s specifications. Fluctuations in voltage can lead to inconsistent performance, so investing in a quality power supply unit can prevent potential issues. Additionally, proper tuning of the servo motor's parameters is crucial. Incorrect tuning can cause overshoot and oscillation, which compromise control accuracy. Regularly reviewing and adjusting the tuning settings based on operational feedback can enhance performance.

Finally, keep an eye on the operating environment. High temperatures and humidity can lead to overheating and premature wear on motor components. Implementing cooling systems and maintaining a clean workspace can extend the motor's lifespan and ensure consistent performance. By understanding these common issues and applying these tips, you can significantly enhance the efficiency of AC servo motors in your applications.

7 Essential Tips for Maximizing Performance with AC Servo Motors

| Tip No. | Tip | Common Issues | Impact on Performance |

|---|---|---|---|

| 1 | Regular Maintenance | Wear and tear, lubricant degradation | Reduces efficiency and lifespan |

| 2 | Proper Alignment | Misalignment of motor and load | Can cause vibration and overheating |

| 3 | Correct Sizing | Undersized or oversized motors | Reduces torque and efficiency |

| 4 | Feedback Loop Calibration | Improperly calibrated sensors | Can lead to position errors and slow response |

| 5 | Install Quality Cables | Poor quality or damaged cables | Can cause signal loss and intermittent performance |

| 6 | Environment Control | Extreme temperatures and dust | May lead to overheating and failures |

| 7 | Use Appropriate Settings | Incorrect servo drive settings | Can affect torque, speed, and accuracy |

Key Factors Affecting AC Servo Motor Efficiency in Industrial Applications

In industrial applications, the efficiency of AC servo motors is influenced by several key factors, which can significantly impact overall system performance. According to a report by the International Electrotechnical Commission (IEC), improper sizing of servo motors can result in energy losses upwards of 20-30%. Selecting the right motor for specific operational demands is crucial; over or under-sizing can lead to increased heat generation and reduced lifespan.

Another critical factor is the quality of feedback devices used in servo systems. High-resolution encoders improve position feedback accuracy, leading to enhanced control precision and efficiency. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that systems using advanced feedback mechanisms exhibit up to 15% better energy efficiency compared to those using standard encoders. Additionally, regular maintenance, including timely lubrication and monitoring of electrical connections, is essential for maintaining optimal performance. Neglecting these aspects can lead to unexpected downtimes, costing manufacturers an estimated $50 billion annually, as reported by the U.S. Department of Energy.

Analyzing the Role of Feedback Systems in Preventing Servo Motor Problems

Feedback systems are critical components in the functionality of AC servo motors, playing a pivotal role in ensuring precision and efficiency in motion control applications. These systems continuously monitor the output performance of the motor by comparing the actual position and speed to the desired set points. By feeding this information back to the controller, any discrepancies can be quickly identified and corrected. This real-time adjustment is essential in preventing common issues such as overshooting, oscillations, or stalls that can significantly degrade performance and lead to costly downtime.

The implementation of sophisticated feedback mechanisms, such as encoders and resolvers, enhances the responsiveness of servo motors. Encoders provide high-resolution position data, while resolvers offer robust performance in harsh environments. Together, they inform the control system about the motor's status, allowing for fine-tuning of its response characteristics. By maintaining optimal communication between the motor and its controller through these feedback systems, engineers can enhance system stability, improve accuracy, and prolong the lifespan of the equipment, ultimately maximizing the overall performance of AC servo motors.

Best Practices for Troubleshooting AC Servo Motor Failures in Production Environments

When working in production environments, AC servo motors are vital for precision and efficiency. However, failures can significantly disrupt operations. To minimize downtime and ensure optimal performance, implementing best practices for troubleshooting is essential.

First, regularly monitor the motor's parameters such as temperature, current, and voltage. This can help identify early signs of potential issues. Additionally, ensure that all connections are secure and free from wear, as loose or corroded connections can lead to intermittent failures.

Another important tip is to conduct periodic maintenance checks, including lubrication and alignment assessments. Keep an eye on the servo drives and control systems as well, since malfunctions in these areas can cascade and affect motor performance. By proactively addressing these aspects, you can prevent small problems from escalating into significant production delays. Regularly updating software and firmware can also enhance efficiency and rectify any bugs that could lead to operational failures.

The Importance of Regular Maintenance in Enhancing AC Servo Motor Longevity

Regular maintenance is crucial for enhancing the longevity and performance of AC servo motors. According to a report by the International Society of Automation, implementing a consistent maintenance schedule can extend the lifespan of servo motors by up to 30%. This level of reliability is vital for industries that rely on precise motion control, such as robotics and manufacturing. It's not just about routine checks; maintenance should include thorough inspections, lubrication of moving parts, and the timely replacement of worn components.

Data from the Machinery Reliability Council indicates that proactive maintenance practices can reduce the overall operational costs associated with motor failures by as much as 50%. Businesses that adopt an effective maintenance program ensure not only a reduction in downtime but also improved energy efficiency, as well-maintained motors operate more smoothly and consume less power. Ultimately, investing time and resources into the regular upkeep of AC servo motors can lead to significant long-term savings and enhanced system performance, reinforcing the importance of a well-structured maintenance plan.

Related Posts

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

Overcoming Common Challenges with Servo Motors: A Deep Dive into Performance and Reliability Issues

-

Understanding the Advantages of Integrated Servo Motors in Modern Automation

-

Addressing Common Calamities in High Torque Motor Procurement: A Global Perspective