How to Choose the Right Industrial Servo Motor for Your Application

In today's highly automated manufacturing landscape, selecting the appropriate industrial servo motor is critical for enhancing efficiency and productivity. According to a recent market research report by MarketsandMarkets, the industrial servo motor market is projected to grow from $8.15 billion in 2020 to $11.92 billion by 2025, at a CAGR of 8.1%. This growth is driven by the increasing demand for automation in various sectors, including robotics, packaging, and textiles. An industrial servo motor not only improves precision and speed in motion control applications but also reduces energy consumption, thereby leading to significant cost savings. As industries continue to evolve, understanding the key factors in choosing the right industrial servo motor—such as torque, speed, and compatibility with control systems—becomes paramount for achieving optimal operational performance.

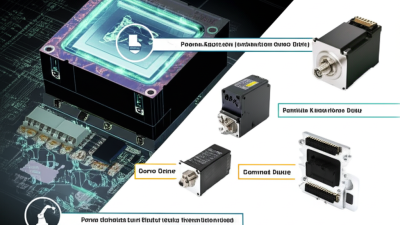

Understanding the Fundamentals: Types of Industrial Servo Motors and Their Applications

When selecting an industrial servo motor, it’s essential to understand the different types available and their corresponding applications. The primary types of servo motors include AC servo motors, DC servo motors, and stepper motors. AC servo motors are known for their high efficiency and are best suited for applications requiring precise control and high speed, such as in robotics and CNC machinery. In contrast, DC servo motors offer simplicity and are often employed in applications where low-speed torque is critical, like in conveyor systems.

Another category, stepper motors, provide excellent positioning accuracy and are typically used in situations where precise movement is necessary, such as 3D printers and camera platforms. The choice among these motors depends largely on the requirements of the specific application, including factors like torque, speed, and accuracy. By understanding these fundamentals and the strengths of each type, engineers can make informed decisions to enhance the performance and efficiency of their systems.

Key Specifications to Consider: Torque, Speed, and Feedback Mechanisms

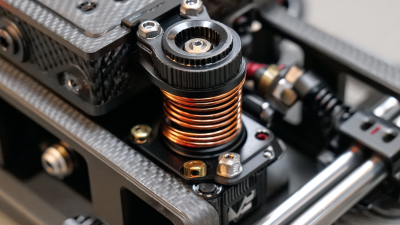

When selecting an industrial servo motor, three critical specifications come to the forefront: torque, speed, and feedback mechanisms. Torque, generally measured in Newton-meters (Nm), determines the motor's ability to perform work. For applications requiring high acceleration or the ability to move heavy loads, prioritize motors with higher torque ratings.

When selecting an industrial servo motor, three critical specifications come to the forefront: torque, speed, and feedback mechanisms. Torque, generally measured in Newton-meters (Nm), determines the motor's ability to perform work. For applications requiring high acceleration or the ability to move heavy loads, prioritize motors with higher torque ratings.

Tips: Always assess your application’s load requirements and consider peak torque values alongside continuous torque ratings. This ensures optimal performance without risking damage to the motor.

Speed is equally essential as it impacts the system's overall responsiveness and efficiency. Servo motors are typically rated for their maximum speed in revolutions per minute (RPM). Choose a motor that can meet or exceed the necessary operational speeds for your application, particularly in dynamic environments where quick adjustments are necessary.

Tips: Review the speed-torque curve of the motor, as it provides insights into how the motor performs under varying loads, enabling smarter decision-making for speed-sensitive applications.

Lastly, feedback mechanisms play a pivotal role in ensuring precision. Common types include encoders and resolvers, which provide real-time data on position and speed. Evaluate the required level of accuracy for your application when selecting a feedback system.

Tips: If your process needs high precision, opt for motors with high-resolution encoders, which can drastically improve control and reduce positioning errors.

Evaluating Environmental Conditions: Operating Temperatures and Space Constraints

When selecting an industrial servo motor, understanding the environmental conditions in which it will operate is essential. For instance, operating temperature is a critical factor. Research indicates that large geographical areas may soon experience heightened heat stress due to climate change, which can influence the thermal performance of servo motors. Most industrial servos are designed to function optimally within specific temperature ranges, typically between -20°C to 60°C. Operating outside these limits may lead to overheating, reduced operational efficiency, or even catastrophic failure. Choosing a motor with a wider temperature tolerance or incorporating thermal management solutions can help mitigate such issues.

Space constraints are another key consideration. The layout of machinery and equipment often determines the size and type of servo motor required. As industries strive for efficiency and compact designs, motors must not only fit into limited spaces but also effectively dissipate heat. Advances in the design of tailored components, such as electrodes and electrolytes for extreme conditions, have shown promise in enhancing performance. The push for sustainable multi-building energy systems further complicates this landscape, as motors may be required to operate in environments that dynamically shift in temperature and humidity. Evaluating these parameters ensures that the selected industrial servo motor aligns well with both operational demands and environmental challenges.

How to Choose the Right Industrial Servo Motor for Your Application - Evaluating Environmental Conditions: Operating Temperatures and Space Constraints

| Motor Type | Operating Temperature Range (°C) | Space Constraints (mm) | Weight (kg) | Power Rating (kW) |

|---|---|---|---|---|

| AC Servo Motor | -20 to 60 | 300 x 300 | 8 | 5 |

| DC Servo Motor | -10 to 50 | 200 x 200 | 6 | 3 |

| Stepper Motor | 0 to 45 | 150 x 150 | 4 | 2 |

| Brushless Servo Motor | -20 to 70 | 250 x 250 | 7 | 4 |

| Industrial Servo Motor | -30 to 80 | 400 x 400 | 10 | 10 |

Energy Efficiency and Performance: The Importance of Servo Motor Ratings

When choosing the right industrial servo motor, energy efficiency is a critical factor to consider. The efficiency levels are categorized into different ratings, such as IE1, IE2, IE3, IE4, and the forthcoming IE5. These ratings not only indicate the motor's energy consumption but also its overall performance in various applications. Motors with higher efficiency ratings consume less power, resulting in lower operational costs and reduced environmental impact. Therefore, selecting a motor with an appropriate efficiency level is essential for optimizing energy usage and enhancing performance.

The AC servo motors and drives market is expanding rapidly, with a projected valuation of USD 15.2 billion in 2024 and a growth rate of 6.6% anticipated through 2034. This growth reflects the increasing demand for energy-efficient solutions across various industries. A comparative study of energy consumption in knuckle boom crane operations highlights the advantages of motor-controlled systems over valve-controlled alternatives. By implementing a two-motor-two-pump setup, significant energy savings and improved performance can be achieved, underscoring the importance of selecting the right servo motor for specific applications.

Cost Analysis: Balancing Initial Investment with Long-Term Benefits and Reliability

When selecting the optimal industrial servo motor, balancing initial costs with long-term reliability and benefits is crucial. According to a report by the International Society of Automation (ISA), firms that invest in high-quality servo motors can realize a 20-30% reduction in maintenance costs over their lifetime. This change not only increases operational efficiency but also enhances machine durability, leading to lower total cost of ownership (TCO).

**Tip:** Conduct a life cycle cost analysis to determine the total expenses associated with purchasing, maintaining, and operating the servo motor. Consider factors such as energy efficiency, operational uptime, and potential savings on repair parts.

Moreover, while the initial investment for premium servo motors may be higher, data from the National Institute of Standards and Technology (NIST) shows that they generally provide better performance, which translates into higher production efficiency and lower energy consumption. This optimization can significantly offset the higher upfront costs in just a few years.

**Tip:** Establish clear performance metrics for your application to quantify the return on investment (ROI) from various servo motor options. This metric-driven approach will guide you toward a more informed purchasing decision.

Related Posts

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

Addressing Common Calamities in High Torque Motor Procurement: A Global Perspective

-

Understanding the Fundamentals of AC Servo Technology: What You Need to Know

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

7 Essential Tips for Choosing the Best High Torque Servo Based on Performance Data

-

Exploring 2025 Tech Trends: How to Choose the Best Frameless Motor for Your Business Needs