Understanding the Advantages of AC Servo Drives in Modern Automation Solutions

In today's rapidly evolving industrial landscape, the integration of automation technologies is critical for enhancing operational efficiency and productivity. One standout component in this arena is the AC servo drive, which has gained significant traction due to its ability to deliver precise control of motion and speed, ultimately leading to improved system performance. According to a report by MarketsandMarkets, the global AC servo drive market is projected to grow from $8.9 billion in 2020 to $13.2 billion by 2025, driven by increasing demand for automation in manufacturing processes.

The efficiency and responsiveness of AC servo drives make them ideal for applications ranging from robotics to CNC machinery, enabling manufacturers to achieve higher production rates with minimal waste. As industries continue to embrace the fourth industrial revolution, understanding the myriad advantages of AC servo drives becomes essential for stakeholders looking to leverage cutting-edge automation solutions.

Advantages of AC Servo Drives in Automation Applications

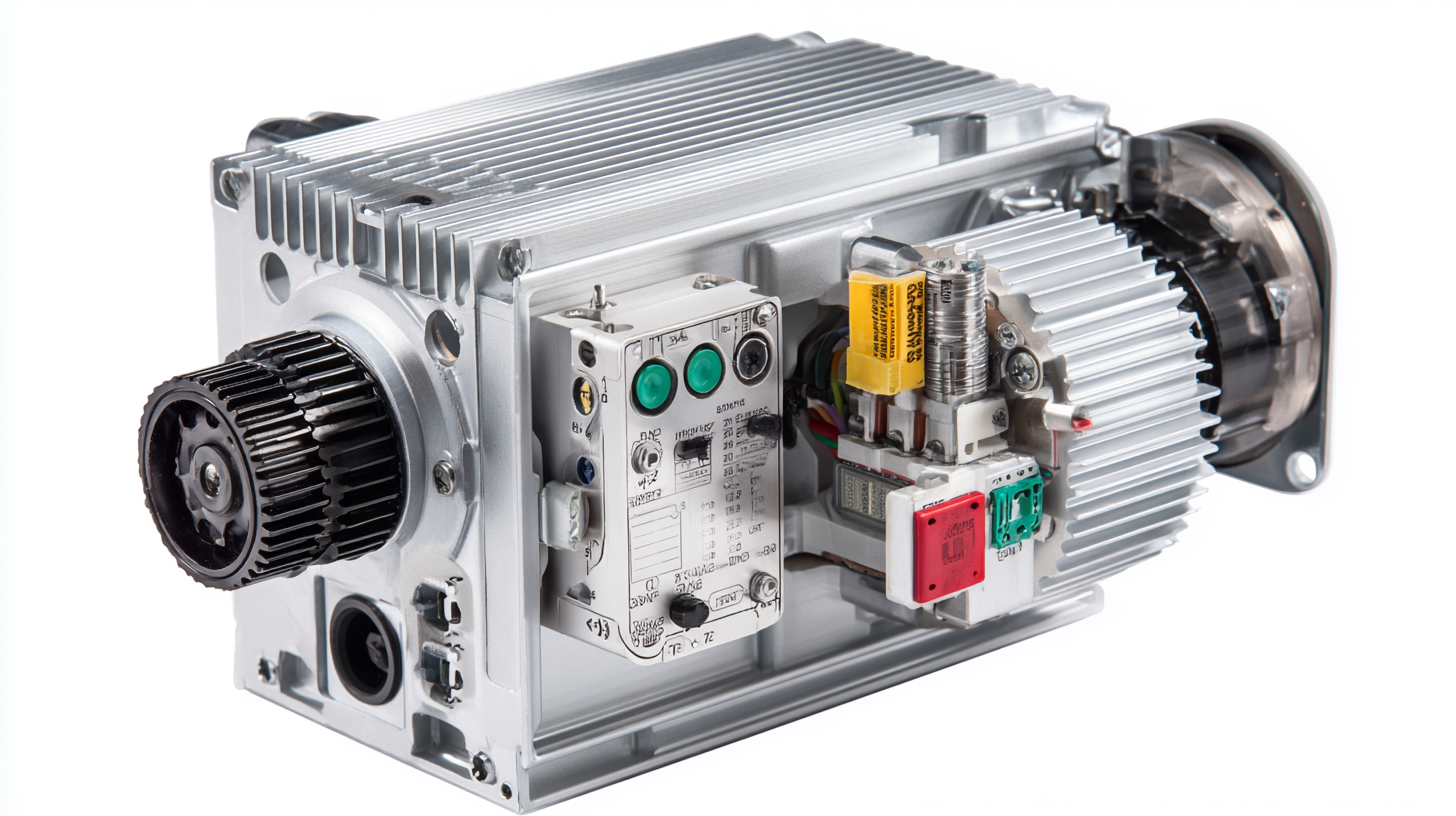

AC servo drives have become increasingly popular in modern automation applications due to their remarkable advantages that enhance performance and efficiency. One of the primary benefits of AC servo drives is their precise control over speed and position. This capability is essential in industries where accuracy is paramount, such as robotics and CNC machinery. By providing feedback through encoders, AC servo drives allow for real-time adjustments, ensuring that operations are executed with high fidelity and minimal error.

Another significant advantage of AC servo drives is their energy efficiency. Compared to traditional DC drives, AC servo systems can operate more effectively under varying loads, reducing energy consumption and operational costs. This is particularly important in environments that rely on continuous operations, where even small savings can lead to substantial reductions in electricity expenses over time. Furthermore, these drives offer a longer lifespan with reduced maintenance needs, which translates into lower overall costs for enterprises while enhancing productivity and reliability in automation processes.

Understanding the Advantages of AC Servo Drives in Modern Automation Solutions

| Advantage | Description | Impact on Automation |

|---|---|---|

| High Precision | AC servo drives provide accurate control of position, speed, and torque. | Improves product quality and reduces waste. |

| Fast Response | Quick adjustments to changes in load and speed. | Enhances efficiency in dynamic applications. |

| Energy Efficiency | AC servo drives optimize energy consumption through advanced control algorithms. | Reduces operational costs and environmental impact. |

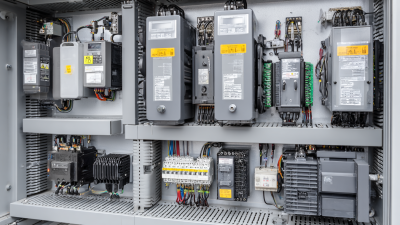

| Compact Size | Smaller footprint compared to other motor drive technologies. | Saves space in control cabinets and machinery. |

| Reduced Maintenance | AC servo motors have fewer parts and wear items, leading to lower maintenance requirements. | Increases uptime and minimizes maintenance costs. |

Key Features of AC Servo Drives That Enhance Performance

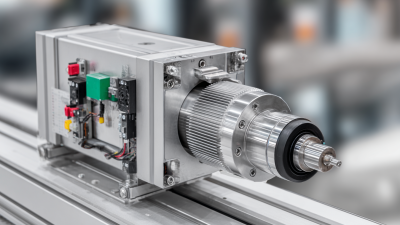

AC servo drives have become increasingly popular in modern automation solutions due to their key features that enhance performance. One of the most significant advantages is their high precision and accuracy. AC servo drives utilize closed-loop control systems, allowing for real-time feedback and adjustments to position and speed. This capability ensures that machinery can operate with minimal error, making them ideal for applications requiring meticulous control, such as robotics and CNC machining.

Another important feature of AC servo drives is their ability to provide high torque at low speeds. This characteristic is essential for applications that demand consistent power without sacrificing performance, especially in heavy-load environments. Additionally, AC servo drives are known for their excellent energy efficiency. They minimize energy consumption during operation, resulting in lower operating costs and a reduced environmental impact. These combined attributes make AC servo drives a superior choice for industries seeking reliable and efficient automation solutions.

Understanding the Advantages of AC Servo Drives in Modern Automation Solutions

Comparison of AC Servo Drives with Traditional Drive Systems

In recent years, the manufacturing sector has experienced a significant shift towards automation, leading to the growing adoption of AC servo drives over traditional drive systems. According to a report by MarketsandMarkets, the global servo motors and drives market is projected to reach $12.3 billion by 2025, with a growth rate of 7.8% from 2020 to 2025. This surge indicates a clear preference for AC servo drives, driven largely by their superior performance characteristics.

When comparing AC servo drives to traditional DC systems, one of the most noteworthy advantages is their efficiency and precision. AC servo drives utilize closed-loop control, offering better torque production and speed regulation than their DC counterparts, which typically employ open-loop systems. Furthermore, AC servo systems are less prone to wear and maintenance issues, resulting in lower operational costs over time. A study by Technavio highlights that industries utilizing AC servo drives see a reduction in energy consumption by up to 30%, making them an economically viable choice for modern manufacturing environments. The ability to maintain high accuracy and consistent performance under varying load conditions solidifies AC servo drives as the preferred option for automation projects in diverse sectors.

Impact of AC Servo Drives on Energy Efficiency and Cost Savings

AC servo drives have emerged as a critical component in modern automation solutions, primarily due to their significant impact on energy efficiency and cost savings. As manufacturing industries increasingly adopt automated systems, the demand for advanced servo motors and drives has surged, driving the market size towards an estimated USD 29.22 billion. This growth can be attributed to the superior performance of AC servo drives, which not only enhance precision in motion control but also significantly reduce energy consumption compared to traditional systems.

The operational efficiency afforded by AC servo drives translates directly into cost savings for businesses. By optimizing energy usage during operations, these drives help reduce electricity bills and improve overall productivity. Moreover, their ability to offer precise control over machinery enables higher production rates and better product quality, thereby minimizing material waste and leading to significant financial benefits. As industries seek to streamline their processes and reduce expenses, the adoption of AC servo drives is poised to continue its upward trajectory, solidifying their position as essential tools in the quest for greater energy efficiency and operational excellence.

Future Trends and Developments in AC Servo Drive Technology

The development of AC servo drive technology is witnessing significant advancements as industries increasingly focus on automation solutions. The integration of intelligent control algorithms and advanced sensor technologies is enhancing the performance and efficiency of these systems. As manufacturers pursue energy-efficient practices, the demand for AC servo drives is projected to grow, driven by their reduced energy consumption and improved responsiveness.

Looking ahead, the trends in AC servo drive technology will likely be shaped by innovations in artificial intelligence and machine learning, which can optimize control processes, predict maintenance needs, and further enhance energy management. Additionally, the shift toward sustainable manufacturing practices is expected to drive research and development in AC servo technology, aligning with the broader goals of reducing carbon footprints and improving overall productivity.

The upcoming years promise exciting developments that will redefine operational capabilities in various sectors, particularly in manufacturing and automation.

Related Posts

-

Top Strategies for Maximizing Performance with Best AC Servo Drives

-

Explore the Technical Specifications of the Best Servo Drives and How to Choose the Right One for Your Needs

-

7 Essential Tips for Maximizing Performance with AC Servo Motors

-

Understanding the Fundamentals of AC Servo Technology: What You Need to Know

-

How to Choose the Right Industrial Servo Motor for Your Application

-

7 Reasons Why Your Factory Needs an AC Servo Motor Today