2025 Guide: How to Choose the Best Small Servo Motor for Your Robotics Project

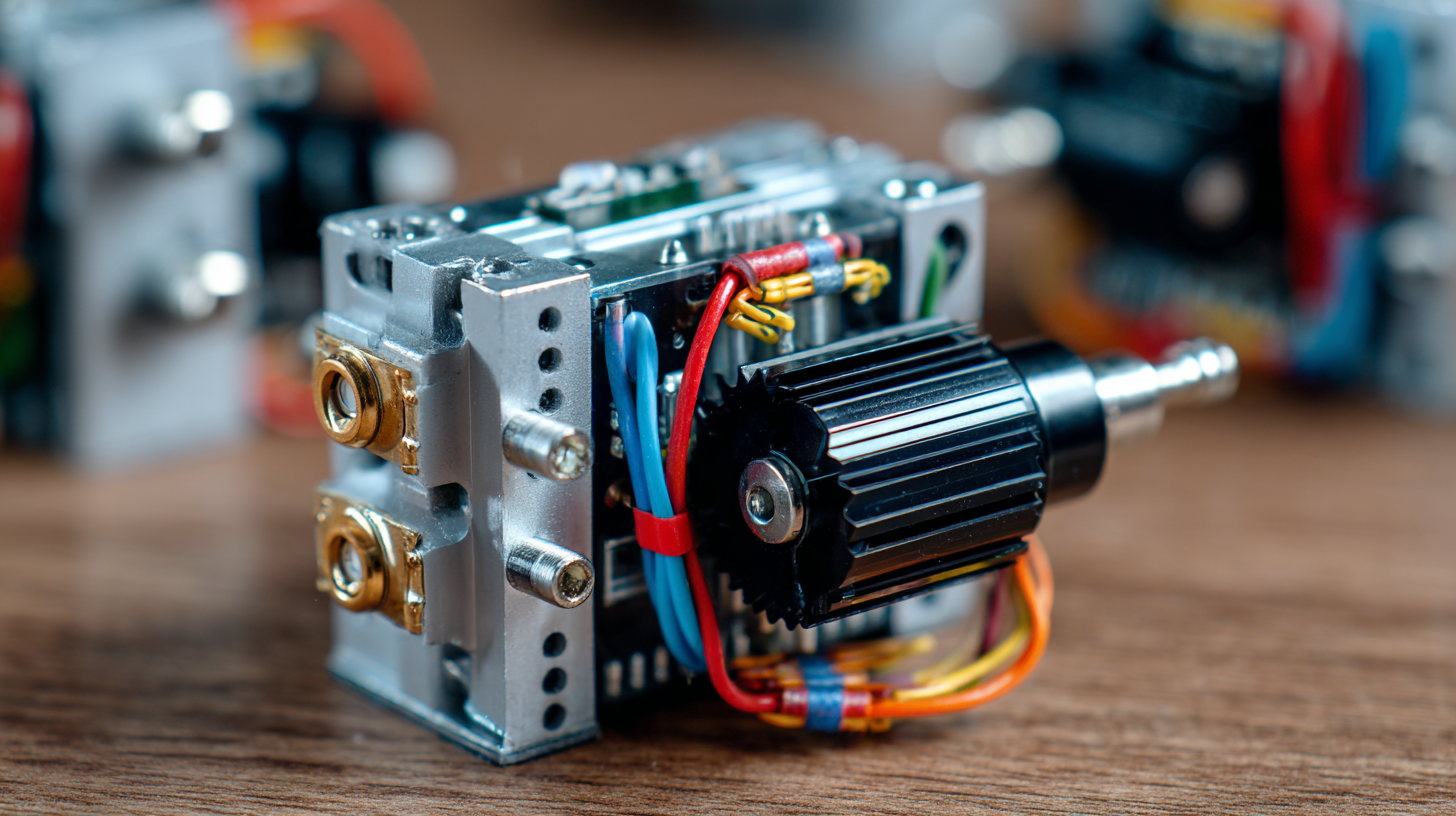

When embarking on a robotics project, selecting the right components is crucial for ensuring efficiency and performance. One of the key elements in many robotic systems is the small servo motor. These compact yet powerful devices offer precise movement and control, making them an ideal choice for a variety of applications, from hobbyist projects to advanced industrial automation. However, with countless options available on the market, choosing the best small servo motor can be a daunting task.

In this guide, we will explore the essential factors to consider when selecting a small servo motor for your robotics project. From understanding specifications such as torque and speed to evaluating compatibility with your project’s design and power requirements, we will provide you with valuable insights and practical tips. Whether you are a beginner looking to create your first robot or an experienced engineer seeking to enhance your designs, this guide will equip you with the knowledge necessary to make informed decisions and optimize your robotics projects for success.

Understanding the Role of Servo Motors in Robotics Projects

Servo motors play a pivotal role in robotics projects by providing precise control over angular position, velocity, and acceleration. These motors are crucial for applications that require accurate movement, such as robotic arms, drones, and automated vehicles. By utilizing a feedback system, servo motors can maintain their position against external disturbances, ensuring that robotic systems perform with high precision and reliability. This ability to adjust and adapt in real-time is essential for complex tasks, making them indispensable in many robotic applications.

Moreover, the selection of the right servo motor can significantly influence the performance of a robotics project. Factors such as torque, speed, size, and power consumption should be carefully considered based on the specific requirements of the task at hand. For instance, a robotic arm designed for intricate assembly may demand high torque and precise movements, while a small aerial drone would benefit from lightweight, energy-efficient motors. Understanding the unique functions and specifications of various servo motors allows engineers and hobbyists to tailor their projects effectively, ensuring optimal performance and outcomes.

Key Factors to Consider When Selecting Small Servo Motors

When selecting small servo motors for various applications such as automotive steering columns, healthcare robotics, and industrial automation, several key factors must be considered to ensure optimal performance. One crucial aspect is the torque rating. For instance, automotive applications typically require servo motors with higher torque to handle the dynamic loads encountered during operation. Industry reports indicate that servo motors operating in automotive applications average a torque range of 1.5 to 6 Nm. Understanding the torque needs based on duty cycles and load characteristics is essential for achieving efficiency and reliability.

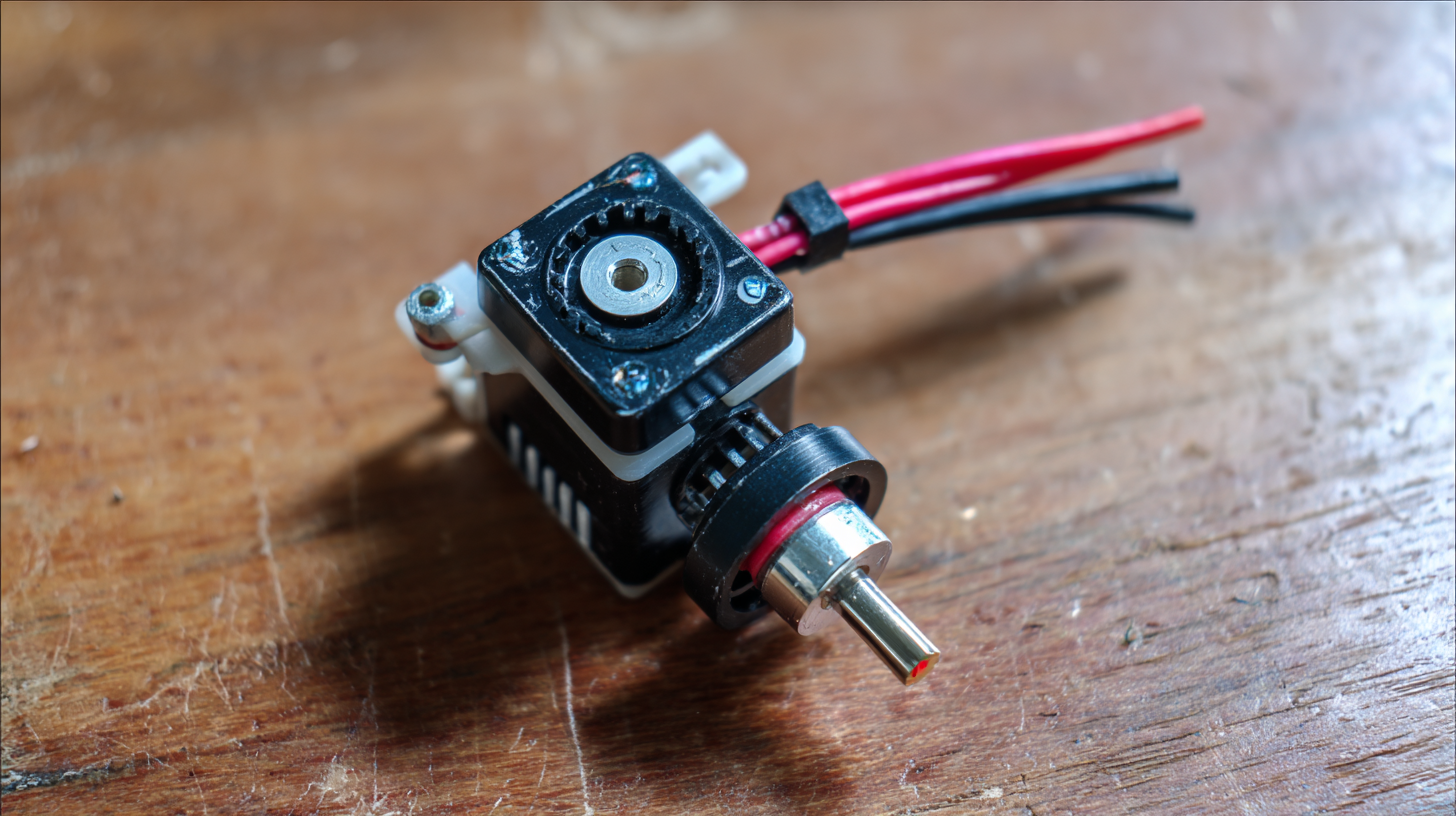

Another important factor is the precision of positioning. In the medical field, particularly in robotic surgeries or rehabilitation devices, servo motors with high precision and repeatability are non-negotiable. Standard precision for medical applications is often within 0.01 degrees, ensuring that each movement is meticulously controlled for patient safety. Additionally, selecting a servo motor with appropriate feedback systems, such as encoders, can significantly enhance the accuracy and responsiveness of the device. Industry projections suggest that the demand for precision-driven servo motors in healthcare robotics is expected to grow by over 15% annually, highlighting the critical nature of these specifications in modern robotics projects.

2025 Guide: Factors to Consider When Choosing Small Servo Motors

Comparing Digital and Analog Servo Motors for Performance

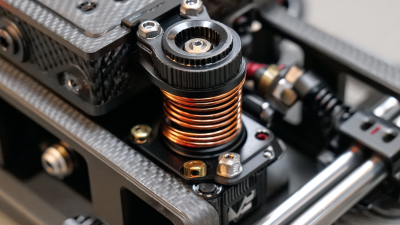

When choosing between digital and analog servo motors for your robotics project, understanding their performance characteristics is crucial. Digital servo motors have inherent advantages, such as higher precision and faster response times, making them more suitable for applications requiring rapid movements and dynamic adjustments. This performance boost is particularly valuable in robotics where accuracy and quick reactions are paramount, especially in complex environments.

On the other hand, analog servo motors, while generally simpler and more cost-effective, offer reliable performance for applications that do not require extreme precision. They are often favored in less demanding scenarios or where budget constraints are a significant factor. However, with the industry's continuous advancements, including the integration of AI in servo systems, the line between digital and analog performance is gradually blurring.

As automation technology evolves, understanding these differences is vital for selecting the right motor type. The current push towards digital transformation in various sectors further emphasizes the relevance of digital servo motors in enhancing operational efficiency and quality, particularly in automotive and industrial applications.

Evaluating Torque, Speed, and Precision in Small Servos

When selecting a small servo motor for your robotics project, it's crucial to evaluate factors such as torque, speed, and precision. According to recent market analysis, the global integrated servo motor market was valued at $5.29 billion in 2023 and is projected to grow significantly, reaching approximately $8.75 billion by 2034, indicating a robust demand for high-performance servos. This growth is driven by the increasing applications of robotics across various industries, highlighting the importance of choosing the right motor for specific requirements.

Torque is a fundamental parameter, influencing the motor's ability to handle loads efficiently. High torque ratings allow the motor to perform under heavier weights, which is essential in robotics where precision movement is key. Speed, measured in revolutions per minute (RPM), determines how fast the servo can operate, making it critical for applications that demand quick responses. Furthermore, precision is often defined by the motor's ability to accurately position itself in relation to inputs, with modern technologies providing advancements in smoothness and dynamics that cater to demanding environments. As the industry continues to innovate, such as the introduction of specialized servos and advanced controllers, engineers must remain informed on these developments to ensure optimal selection for their projects.

Top Recommendations for Reliable Small Servo Motors in 2025

When considering the best small servo motors for your robotics project in 2025, reliability is paramount. One of the top recommendations is the Dynamixel MX-28T. Known for its impressive torque and precise control, this servo motor offers a robust performance that can handle various robotic applications. Its advanced feedback system provides essential data, enabling developers to fine-tune their robots effectively. The MX series also supports daisy chaining, making it ideal for complex projects requiring multiple servos.

Another excellent choice is the Hitec HS-5086WP, a waterproof servo motor that excels in outdoor robotics. This motor stands out for its durability and resistance to harsh environments, making it suitable for projects where reliability is crucial. Additionally, it features a high-speed coreless motor, ensuring responsive movement and precise positioning. With its adaptable specifications, the Hitec HS-5086WP is a versatile option for both amateur and professional robotics enthusiasts alike.

Related Posts

-

Electric Servo Motor Showdown: Which Type Reigns Supreme in Performance and Efficiency?

-

Addressing Common Calamities in High Torque Motor Procurement: A Global Perspective

-

7 Essential Tips for Choosing the Best High Torque Servo Based on Performance Data

-

How to Choose the Right Industrial Servo Motor for Your Application

-

7 Reasons Why High Torque Motors Are Revolutionizing Industrial Applications

-

Unlocking Efficiency: How Industrial Servo Motors Transform Automation in Manufacturing